Cleaning method and service life of Powder metallurgy agricultural machinery parts

- Categories:Industry News

- Author:

- Origin:

- Time of issue:2022-08-03

- Views:

(Summary description)Because powder metallurgy itself has a porous structure, powder metallurgy agricultural machinery parts will have some fine pores inside and on the surface, and the parts will deform and rust when they are affected by water vapor and other hydroxide ions in the air.

Cleaning method and service life of Powder metallurgy agricultural machinery parts

(Summary description)Because powder metallurgy itself has a porous structure, powder metallurgy agricultural machinery parts will have some fine pores inside and on the surface, and the parts will deform and rust when they are affected by water vapor and other hydroxide ions in the air.

- Categories:Industry News

- Author:

- Origin:

- Time of issue:2022-08-03 11:12

- Views:

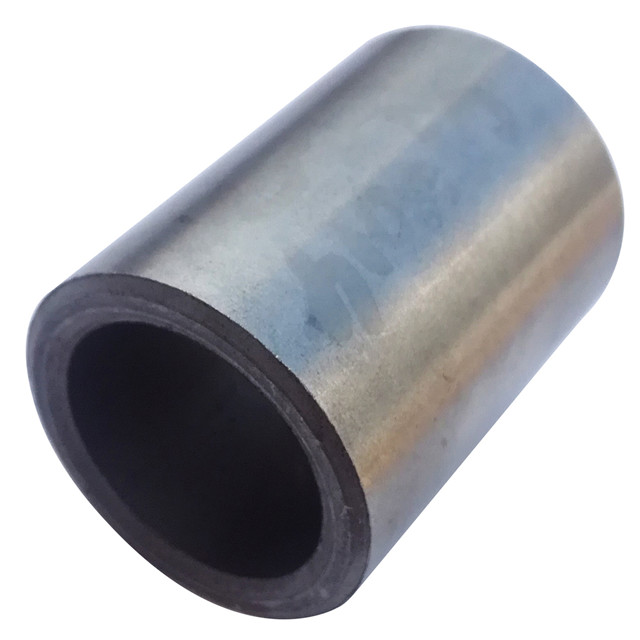

Because powder metallurgy itself has a porous structure, powder metallurgy agricultural machinery parts will have some fine pores inside and on the surface, and the parts will deform and rust when they are affected by water vapor and other hydroxide ions in the air. The purpose of cleaning is to deal with various rust problems.

1: Water-soluble cleaning agent cleaning

The water-soluble cleaning agent can effectively remove part of the rust and improve the brightness of the parts. The use of water-soluble cleaning agents needs to increase the process of dehydration and rust prevention. If there is no dehydration treatment, a series of problems on the surface of the parts can be solved. , but with the increase of time, the Powder metallurgy agricultural machinery parts will have a certain degree of corrosion from the inside in place. If there is internal corrosion, this part will not be able to be used normally.

2: Vacuum hydrocarbon ultrasonic cleaning

Powder metallurgy agricultural machinery parts manufacturers tell you that vacuum hydrocarbon ultrasonic cleaning is a cleaning method with a relatively high comprehensive cost. For some bearings with high precision, parts in various engines and small parts need to use vacuum hydrocarbon cleaning. The method of cleaning can avoid the formation of rust from the inside to the outside. The hydrocarbon solvent is easy to volatilize in the normal temperature environment, and it is difficult to store it. The environmental factors and the cost of use should be comprehensively considered.

3: Cleaning of kerosene and white oil

The cleaning of kerosene and white oil is a traditional cleaning method. Due to the continuous improvement of the precision requirements for Powder metallurgy agricultural machinery parts, these two types of cleaning methods are gradually eliminated. Compared with kerosene and white oil, white oil has relatively better anti-rust ability, but due to its relatively large tension and certain requirements for density, not all parts can be cleaned with these two solvents.

Scan the QR code to read on your phone

Interactive message

-

Tel

-

Tel

-

Back to top

Our company cooperate with hundreds of well-known enterprises such as automobile bearing, gasoline / diesel engine, textile machinery, food machinery, agricultural machinery, home appliances, motor, electric tools industry for a long time and enjoy a good reputation. Some products are exported to developed countries such as Europe and the United States. Welcome new and old customers come to negotiate and cooperate!

Quick navigation

QR code

Contact us

Address:No. 148, yinlei Road, Laizhou City, Yantai City, Shandong

Tel:+86-0535-2213773

Fax:+86-0535-2203773

Tel:+86-13853563291

E-mail:lujun@sinterpart.com

QQ:2867251632

WeChat:鲁俊粉末冶金

Linkman: Lianlian Yu

Copyright © 2021 Laizhou Lujun Powder Metallurgy Co., Ltd. 鲁ICP备09032343号

Powered by www.300.cn This site supports IPV6 access