Metallurgy Core Shaft Casting Roll Cleaning Method

- Categories:Industry News

- Author:

- Origin:

- Time of issue:2022-03-02

- Views:

(Summary description)Metallurgy Core Shaft manufacturers tell you that with the rapid development of social technology, the development of industrial technology is even more rapid. The functional design of industrial equipment in industrial production is very ingenious.

Metallurgy Core Shaft Casting Roll Cleaning Method

(Summary description)Metallurgy Core Shaft manufacturers tell you that with the rapid development of social technology, the development of industrial technology is even more rapid. The functional design of industrial equipment in industrial production is very ingenious.

- Categories:Industry News

- Author:

- Origin:

- Time of issue:2022-03-02 17:43

- Views:

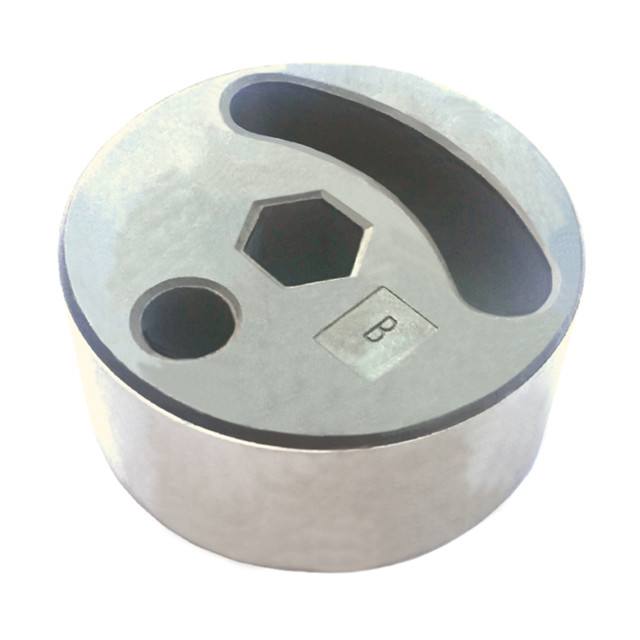

Metallurgy Core Shaft manufacturers tell you that with the rapid development of social technology, the development of industrial technology is even more rapid. The functional design of industrial equipment in industrial production is very ingenious. In all parts, parts of various shapes such as cylinders are used to meet the link of the functions of each part. Among them, the Metallurgy Core Shaft continuous casting roll is a common type of equipment components, and its characteristics have its own special advantages. These are also based on the Metallurgy Core Shaft continuous casting rolls are carefully processed during the processing process. Next, let us work together Read more about how Metallurgy Core Shaft rolls are cleaned.

1. Ultrasonic cleaning method. The Metallurgy Core Shaft manufacturer tells you to dip the anilox roller in a tank of an ultrasonic cleaning system filled with chemical cleaning solution. The frequency conversion device in the tank sends high-frequency sound waves to break the dried ink in the cell and flow away with the cleaning solution. . Attention should be paid to the use of ultrasonic cleaning: excessive cleaning time will cause damage to the mesh. The higher the line number of the anilox roller, the shorter the cleaning time;

2. Low pressure jet cleaning method. The Metallurgy Core Shaft manufacturer tells you to use soda powder or plastic beads as cleaning powder, and spray the anilox roller under low pressure to clean the dried ink in the cells, but pay attention to the fact that the spray pressure should not be too high (generally no more than 0.1 MPa), otherwise the ceramic layer of the ceramic anilox roller may fall off from the anilox roller body; other methods: dry ice cleaning method, chemical solvent immersion method, etc.

Through the above understanding, we already know how to clean the continuous casting roll of Metallurgy Core Shaft. Only by cleaning it correctly can the cleaning of its equipment be ensured, thereby reducing the failure rate of the equipment and prolonging the life of its equipment. Improve the quality of produced products.

Scan the QR code to read on your phone

Interactive message

-

Tel

-

Tel

-

Back to top

Our company cooperate with hundreds of well-known enterprises such as automobile bearing, gasoline / diesel engine, textile machinery, food machinery, agricultural machinery, home appliances, motor, electric tools industry for a long time and enjoy a good reputation. Some products are exported to developed countries such as Europe and the United States. Welcome new and old customers come to negotiate and cooperate!

Quick navigation

QR code

Contact us

Address:No. 148, yinlei Road, Laizhou City, Yantai City, Shandong

Tel:+86-0535-2213773

Fax:+86-0535-2203773

Tel:+86-13853563291

E-mail:lujun@sinterpart.com

QQ:2867251632

WeChat:鲁俊粉末冶金

Linkman: Lianlian Yu

Copyright © 2021 Laizhou Lujun Powder Metallurgy Co., Ltd. 鲁ICP备09032343号

Powered by www.300.cn This site supports IPV6 access