Powder metallurgy agricultural machinery parts manufacturers take you to understand the process of powder metallurgy

- Categories:Industry News

- Author:

- Origin:

- Time of issue:2023-03-02

- Views:

(Summary description)According to the manufacturer of Powder metallurgy agricultural machinery parts, powder metallurgy is a process in which metal or metal powder (or a mixture of metal powder and non-metal powder) is used as a raw material to form and sinter metal materials, composite materials and various products.

Powder metallurgy agricultural machinery parts manufacturers take you to understand the process of powder metallurgy

(Summary description)According to the manufacturer of Powder metallurgy agricultural machinery parts, powder metallurgy is a process in which metal or metal powder (or a mixture of metal powder and non-metal powder) is used as a raw material to form and sinter metal materials, composite materials and various products.

- Categories:Industry News

- Author:

- Origin:

- Time of issue:2023-03-02 17:15

- Views:

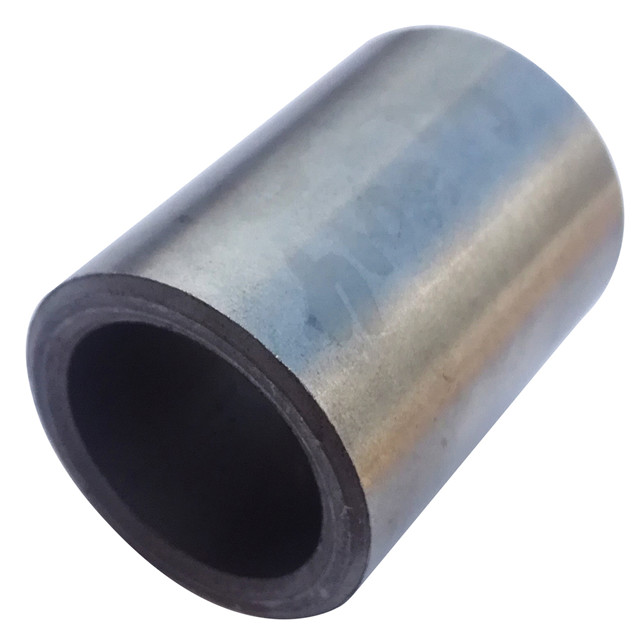

According to the manufacturer of Powder metallurgy agricultural machinery parts, powder metallurgy is a process in which metal or metal powder (or a mixture of metal powder and non-metal powder) is used as a raw material to form and sinter metal materials, composite materials and various products. The generalized powder metallurgy product industry includes iron and stone tools, cemented carbide, magnetic materials and powder metallurgy products. Narrowly defined P/M products only refer to P/M products, including P/M parts (the vast majority), oil bearings and metal injection molding products. Today we will delve into this process.

Process characteristics of powder metallurgy:

1. The density of the product is controllable, such as porous materials, materials with good density, etc.;

2. Fine grain, uniform microstructure, no component segregation;

3. Near forming, raw material utilization rate and > 95%;

4. Less cutting, cutting only 40~50%;

5. The composition of the material is controllable, which is conducive to the preparation of composite materials;

6. Preparation of insoluble metals, ceramic materials and nuclear materials.

The basic process of powder metallurgy:

1. Grinding: Grinding is the process of making raw materials into powder. Commonly used pulverization methods include redox method and mechanical pulverization method.

2. Mixing: Mixing is the process of mixing various required powders evenly in a certain proportion to make billet powders. According to different requirements, it can be divided into dry type, semi-dry type and wet type.

3. Forming: Forming is the process of putting uniformly mixed materials into a die to form a blank with a certain shape, size and density. Forming methods are basically divided into pressure forming and non-pressure forming. Pressure forming is used more in forming.

4. Sintering: Powder metallurgy agricultural machinery parts manufacturers said that sintering is the key process of powder metallurgy. After forming, the press is sintered to obtain the desired final physical and mechanical properties. Sintering is divided into single-system sintering and multi-system sintering. In addition to ordinary sintering, there are also special sintering processes such as loose sintering, smelting, and hot pressing.

5. Post-processing: After sintering, various methods are adopted according to different requirements of the product. Such as finishing, oil immersion, machining, heat treatment, electroplating, etc. In addition, in recent years, some new technologies such as rolling and forging have also been applied to the processing of powder metallurgy materials after sintering, and good results have been achieved.

Powder metallurgy agricultural machinery parts manufacturers said that powder metallurgy products have a wide range of applications, from ordinary machinery manufacturing to precision instruments; from hardware tools to large machinery; from electronic products to automobile manufacturing; from civil industry to military industry; from general technology to cutting-edge High technology can be seen in the powder metallurgy process. Powder metallurgy agricultural machinery parts manufacturers tell you that the aviation industry will also use it, but powder metallurgy materials used in the aviation industry, a class of special functional materials, such as friction materials, anti-friction materials, sealing materials, filter materials, etc., are mainly used in aircraft and Engine auxiliary machines, instruments and airborne equipment. The other is high-temperature high-strength structural materials, which are mainly used as important structural parts on aircraft mainframes.

Scan the QR code to read on your phone

Interactive message

-

Tel

-

Tel

-

Back to top

Our company cooperate with hundreds of well-known enterprises such as automobile bearing, gasoline / diesel engine, textile machinery, food machinery, agricultural machinery, home appliances, motor, electric tools industry for a long time and enjoy a good reputation. Some products are exported to developed countries such as Europe and the United States. Welcome new and old customers come to negotiate and cooperate!

Quick navigation

QR code

Contact us

Address:No. 148, yinlei Road, Laizhou City, Yantai City, Shandong

Tel:+86-0535-2213773

Fax:+86-0535-2203773

Tel:+86-13853563291

E-mail:lujun@sinterpart.com

QQ:2867251632

WeChat:鲁俊粉末冶金

Linkman: Lianlian Yu

Copyright © 2021 Laizhou Lujun Powder Metallurgy Co., Ltd. 鲁ICP备09032343号

Powered by www.300.cn This site supports IPV6 access