Powder metallurgy auto parts manufacturers take you to understand the development trend of powder metallurgy parts

- Categories:Industry News

- Author:

- Origin:

- Time of issue:2022-04-26

- Views:

(Summary description)Powder metallurgy auto parts manufacturers tell you that according to the statistics before 2010, there are 105 kinds of powder metallurgy parts, 66 kinds are used in automobiles, including 23 kinds of engine parts, 17 kinds of transmission parts, 26 kinds of other parts, powder metallurgy auto parts Manufacturers tell you that automotive engines and gearboxes are the two most widely used fields of powder metallurgy components.

Powder metallurgy auto parts manufacturers take you to understand the development trend of powder metallurgy parts

(Summary description)Powder metallurgy auto parts manufacturers tell you that according to the statistics before 2010, there are 105 kinds of powder metallurgy parts, 66 kinds are used in automobiles, including 23 kinds of engine parts, 17 kinds of transmission parts, 26 kinds of other parts, powder metallurgy auto parts Manufacturers tell you that automotive engines and gearboxes are the two most widely used fields of powder metallurgy components.

- Categories:Industry News

- Author:

- Origin:

- Time of issue:2022-04-26 14:04

- Views:

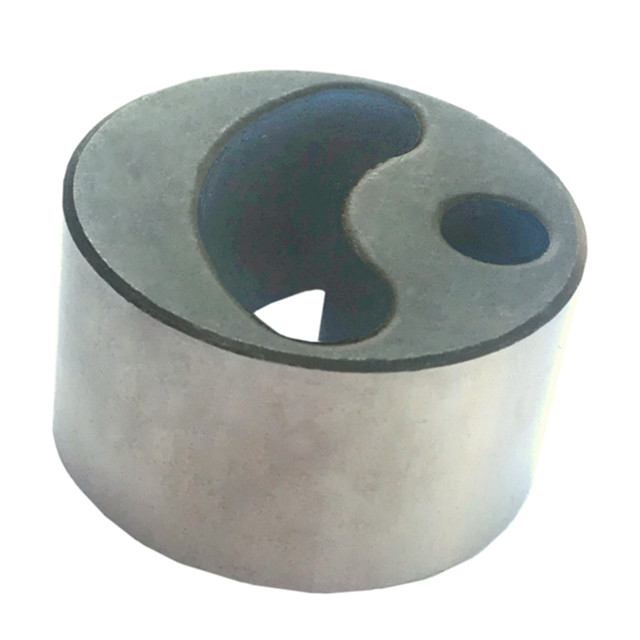

Powder metallurgy auto parts manufacturers tell you that according to the statistics before 2010, there are 105 kinds of powder metallurgy parts, 66 kinds are used in automobiles, including 23 kinds of engine parts, 17 kinds of transmission parts, 26 kinds of other parts, powder metallurgy auto parts Manufacturers tell you that automotive engines and gearboxes are the two most widely used fields of powder metallurgy components.

At present, there are few domestic companies involved in the parts of mid-to-high-end automotive powder metallurgy manufacturers, and domestic high-end automotive powder metallurgy parts still mainly rely on imports. Powder metallurgy auto parts manufacturers tell you that there is still a big gap between domestic companies in terms of production technology, quality control and R&D capabilities compared with foreign companies.

In the future, with the continuous improvement of domestic powder metallurgy technology, the dimensional tolerance and performance parameters of its products will also reach a higher level. With the cost advantage of powder metallurgy products, automobile OEMs will choose powder metallurgy with lower cost. Parts instead of forged and machined parts. At the same time, the production process of powder metallurgy products is about 60% more energy efficient than the traditional metal forming process, and its material utilization rate can reach more than 95%; powder metallurgy auto parts manufacturers tell you that the production process has no environmental pollution, green environmental protection, and conforms to The concept of energy saving, emission reduction and sustainable development. Considering the gradual increase in energy conservation and emission reduction policies and the increasing requirements for cost control, domestic enterprises will use powder metallurgy technology to produce auto parts more in the future.

Scan the QR code to read on your phone

Interactive message

-

Tel

-

Tel

-

Back to top

Our company cooperate with hundreds of well-known enterprises such as automobile bearing, gasoline / diesel engine, textile machinery, food machinery, agricultural machinery, home appliances, motor, electric tools industry for a long time and enjoy a good reputation. Some products are exported to developed countries such as Europe and the United States. Welcome new and old customers come to negotiate and cooperate!

Quick navigation

QR code

Contact us

Address:No. 148, yinlei Road, Laizhou City, Yantai City, Shandong

Tel:+86-0535-2213773

Fax:+86-0535-2203773

Tel:+86-13853563291

E-mail:lujun@sinterpart.com

QQ:2867251632

WeChat:鲁俊粉末冶金

Linkman: Lianlian Yu

Copyright © 2021 Laizhou Lujun Powder Metallurgy Co., Ltd. 鲁ICP备09032343号

Powered by www.300.cn This site supports IPV6 access