Powder metallurgy garden tool parts manufacturers take you to understand the basic process of powder metallurgy process

- Categories:Industry News

- Author:

- Origin:

- Time of issue:2022-05-18

- Views:

(Summary description)Powder metallurgy garden tool parts manufacturers tell you that making powder is the first step in powder metallurgy. With the continuous increase of powder metallurgy materials and products and the continuous improvement of their quality.

Powder metallurgy garden tool parts manufacturers take you to understand the basic process of powder metallurgy process

(Summary description)Powder metallurgy garden tool parts manufacturers tell you that making powder is the first step in powder metallurgy. With the continuous increase of powder metallurgy materials and products and the continuous improvement of their quality.

- Categories:Industry News

- Author:

- Origin:

- Time of issue:2022-05-18 14:30

- Views:

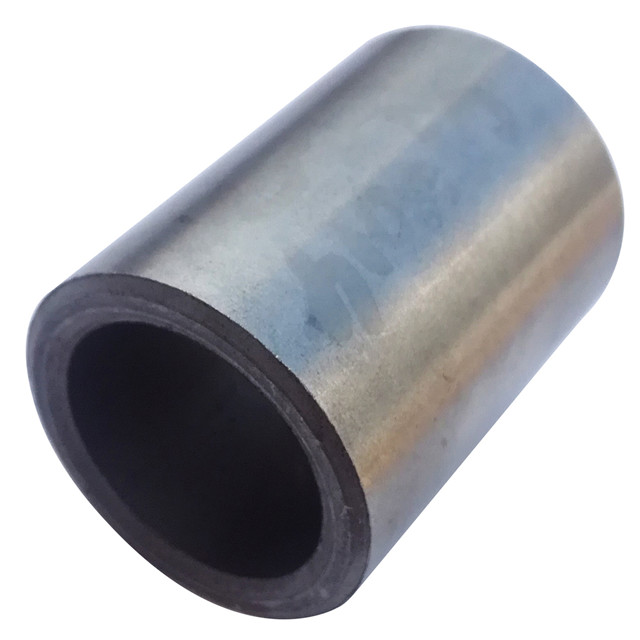

Powder metallurgy garden tool parts manufacturers tell you that making powder is the first step in powder metallurgy. With the continuous increase of powder metallurgy materials and products and the continuous improvement of their quality, more and more types of powders are required to be provided.

The basic process of powder metallurgy process:

1. Preparation of raw material powder. The existing milling methods can be roughly divided into two categories: mechanical methods and physical-chemical methods. The mechanical method can be divided into: mechanical pulverization and atomization; physical and chemical methods are further divided into: electrochemical corrosion method, reduction method, chemical method, reduction-chemical method, vapor deposition method, liquid deposition method and electrolysis method. Among them, the most widely used are reduction method, atomization method and electrolysis method.

2. The powder is formed into a compact of the desired shape. Powder metallurgy garden tool parts manufacturers tell you that the purpose of molding is to make a compact of a certain shape and size, and to make it have a certain density and strength. The molding method is basically divided into pressure molding and pressureless molding. The most widely used compression molding is compression molding. In addition, 3D printing technology can also be used for the production of embryo blocks.

3. Sintering of compacts. Sintering is a critical step in powder metallurgy process. The formed compact is sintered to obtain the desired final physical and mechanical properties. Sintering is further divided into unit-system sintering and multi-system sintering. Powder metallurgy garden tool parts manufacturers tell you that the sintering temperature is lower than the melting point of the metals and alloys used for the solid phase sintering of the unitary system and the multicomponent system; for the liquid phase sintering of the multicomponent system, the sintering temperature is generally lower than the melting point of the refractory components. , which is higher than the melting point of the fusible components. In addition to ordinary sintering, there are special sintering processes such as loose sintering, infusion method, and hot pressing method.

4. Post-processing of products. Powder metallurgy garden tool parts manufacturers tell you that the treatment after sintering can be done in a variety of ways according to different product requirements. Such as finishing, oil immersion, machining, heat treatment and electroplating. In addition, in recent years, some new processes such as rolling and forging have also been applied to the processing of powder metallurgy materials after sintering, and achieved ideal results.

Scan the QR code to read on your phone

Interactive message

-

Tel

-

Tel

-

Back to top

Our company cooperate with hundreds of well-known enterprises such as automobile bearing, gasoline / diesel engine, textile machinery, food machinery, agricultural machinery, home appliances, motor, electric tools industry for a long time and enjoy a good reputation. Some products are exported to developed countries such as Europe and the United States. Welcome new and old customers come to negotiate and cooperate!

Quick navigation

QR code

Contact us

Address:No. 148, yinlei Road, Laizhou City, Yantai City, Shandong

Tel:+86-0535-2213773

Fax:+86-0535-2203773

Tel:+86-13853563291

E-mail:lujun@sinterpart.com

QQ:2867251632

WeChat:鲁俊粉末冶金

Linkman: Lianlian Yu

Copyright © 2021 Laizhou Lujun Powder Metallurgy Co., Ltd. 鲁ICP备09032343号

Powered by www.300.cn This site supports IPV6 access