Powder metallurgy manufacturer takes you to understand why powder metallurgy products are vulcanized

- Categories:Industry News

- Author:

- Origin:

- Time of issue:2022-04-07

- Views:

(Summary description)Powder metallurgy manufacturer tells you that powder metallurgy products have been widely used in automobiles, home appliances, construction machinery, power tools and other fields, and the fields of application are no longer limited to the machinery and equipment industry.

Powder metallurgy manufacturer takes you to understand why powder metallurgy products are vulcanized

(Summary description)Powder metallurgy manufacturer tells you that powder metallurgy products have been widely used in automobiles, home appliances, construction machinery, power tools and other fields, and the fields of application are no longer limited to the machinery and equipment industry.

- Categories:Industry News

- Author:

- Origin:

- Time of issue:2022-04-07 16:14

- Views:

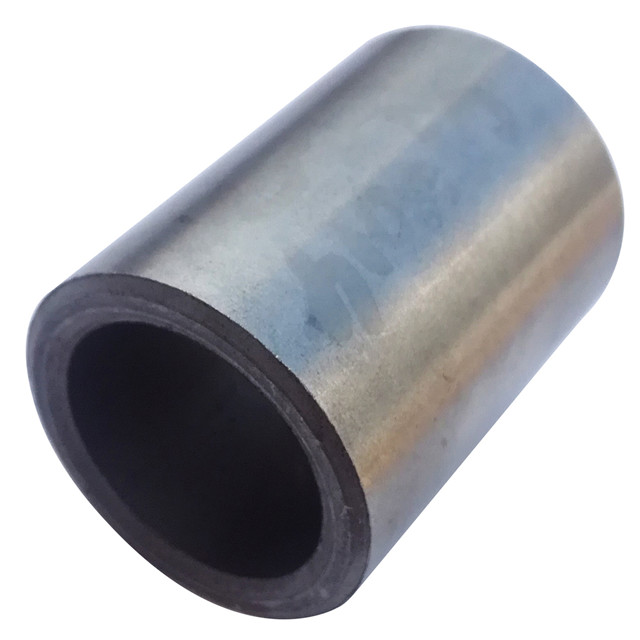

Powder metallurgy manufacturer tells you that powder metallurgy products have been widely used in automobiles, home appliances, construction machinery, power tools and other fields, and the fields of application are no longer limited to the machinery and equipment industry. The manufacturing cost of powder metallurgy products is relatively cheap. Many industry manufacturers like it. So why should powder metallurgy products be vulcanized? Today Powder metallurgy manufacturer will introduce to you:

When vulcanization is used as anti-friction material in powder metallurgy products, iron-based oil-impregnated bearings are the most widely used. The sintered oil-impregnated bearing (with graphite content of 1%-4%) has a simple manufacturing process and low cost, and can replace friction-reducing materials such as bronze and babbitt under the condition of PV<18-25 kg·m/cm²·sec. However, under heavy working conditions, such as high sliding speed and large unit load on the friction surface, the wear resistance and life of sintered parts will decrease rapidly. Powder metallurgy manufacturer tells you that in order to improve the anti-friction performance of porous iron-based anti-friction parts, reduce the friction coefficient, and increase the working temperature to expand its range of use, vulcanization treatment is a method worthy of promotion.

Sulfur and most sulfides have certain lubricating properties. Iron sulfide is a good solid lubricant, especially under the condition of dry friction, the existence of iron sulfide has good anti-seizure.

Powder metallurgy iron-based products can be impregnated with a considerable amount of sulfur by using their capillary pores. After heating, the sulfur and iron on the surface of the pores can be formed into iron sulfide, which is evenly distributed throughout the product and plays a good role in lubrication on the friction surface. effect, and can improve machinability. The vulcanized product has smooth friction and cutting surfaces.

Porous sintered iron has good dry friction properties after being vulcanized. It is a satisfactory self-lubricating material under the working conditions of no oil lubrication (that is, no oil is allowed or cannot be refueled), and it has a good anti-seizure property and reduces the phenomenon of gnawing on the shaft. In addition, the friction properties of this material are different from those of general anti-friction materials. Powder metallurgy manufacturer tells you that with the increase of specific pressure, the friction coefficient of general materials does not change much. When the specific pressure exceeds a certain value, the friction coefficient increases sharply. However, the friction coefficient of porous sintered iron after vulcanization treatment decreases with the increase of specific pressure in a large specific pressure range. This is a valuable property of anti-friction materials.

Powder metallurgy manufacturer tells you that sintered iron-based oil-impregnated bearings after vulcanization can work smoothly below 250℃.

Scan the QR code to read on your phone

Interactive message

-

Tel

-

Tel

-

Back to top

Our company cooperate with hundreds of well-known enterprises such as automobile bearing, gasoline / diesel engine, textile machinery, food machinery, agricultural machinery, home appliances, motor, electric tools industry for a long time and enjoy a good reputation. Some products are exported to developed countries such as Europe and the United States. Welcome new and old customers come to negotiate and cooperate!

Quick navigation

QR code

Contact us

Address:No. 148, yinlei Road, Laizhou City, Yantai City, Shandong

Tel:+86-0535-2213773

Fax:+86-0535-2203773

Tel:+86-13853563291

E-mail:lujun@sinterpart.com

QQ:2867251632

WeChat:鲁俊粉末冶金

Linkman: Lianlian Yu

Copyright © 2021 Laizhou Lujun Powder Metallurgy Co., Ltd. 鲁ICP备09032343号

Powered by www.300.cn This site supports IPV6 access