Selection criteria for Spline bushing products

- Categories:Industry News

- Author:

- Origin:

- Time of issue:2021-10-18

- Views:

(Summary description)The manufacturer of Spline bushing tells you that the spline connection consists of an internal spline and an external spline.

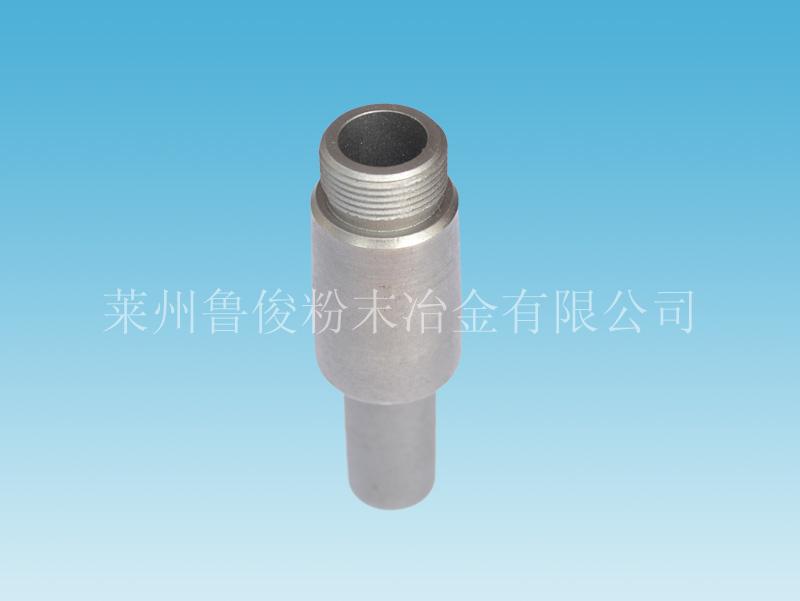

Selection criteria for Spline bushing products

(Summary description)The manufacturer of Spline bushing tells you that the spline connection consists of an internal spline and an external spline.

- Categories:Industry News

- Author:

- Origin:

- Time of issue:2021-10-18 16:55

- Views:

The manufacturer of Spline bushing tells you that the spline connection consists of an internal spline and an external spline. The inner and outer splines are multi-tooth parts, the splines on the inner cylindrical surface are inner splines, and the splines on the outer cylindrical surface are outer splines. Obviously, the spline connection is the development of the flat key connection in terms of number. The spline is a standard structure. The flat key connection is often used for the connection of gears or couplings with interference fits and shafts. Spline bushing manufacturers tell you that there is usually no interference in the spline connection, so the connected parts need to be axially fixed. The spline is fast, easy and excellent. The spline connection has high load-bearing capacity and good alignment, but the manufacturing cost is high, and it needs to be processed with a special tool.

Bushing inspection standard:

1. The Spline bushing manufacturer tells you that the surface of the sample should be free of bubbles, burrs, deformation, uniform material, and no irritating odor.

2. Size

(1) Testing related dimensions with vernier calipers should meet the requirements of related technologies and drawings.

(2) After the shaft sleeve is matched with the rotating shaft, the rotor is vertically downward, and the shaft sleeve will not slide freely under the action of its own weight.

3. Heat resistance and aging resistance test

(1) After the sample is subjected to the 125℃/1h ball pressure test, the indentation should be ≤2mm, and there is no deformation by visual inspection.

(2) After putting the sample in the oven at 120°C/96 hours, visually check that the shaft sleeve has no embrittlement or deformation.

4. Combustion resistance test

The flame retardant grade is VW-1, and it should be extinguished within 15S after burning with alcohol lamp for 15S.

5. Packaging and logo

(1) The Spline bushing manufacturer tells you that the packaging should be firm, reliable and safe to ensure that the product is not damaged during transportation.

(2) The Spline bushing manufacturer tells you that the supplier's code and name, product name, product quantity, material code, quality inspection mark, production date, etc. should be indicated on the packaging. The mark should be clear and accurate, and there should be no mixed packaging.

(3) The Spline bushing manufacturer tells you that in order to increase the traceability of the product, it is required to mark the production batch number in a conspicuous place on the outer packaging. The supply lot number should be indicated on the product's inspection certificate or the original record of the inspection (experiment).

6. The content of hazardous substances (RoHS Directive)

The manufacturer of Spline bushing tells you that if it is used in RoHS directive models, the materials should comply with the RoHS directive requirements.

The above six points are the inspection standards for Spline bushing products. Welcome to inquire.

Scan the QR code to read on your phone

Interactive message

-

Tel

-

Tel

-

Back to top

Our company cooperate with hundreds of well-known enterprises such as automobile bearing, gasoline / diesel engine, textile machinery, food machinery, agricultural machinery, home appliances, motor, electric tools industry for a long time and enjoy a good reputation. Some products are exported to developed countries such as Europe and the United States. Welcome new and old customers come to negotiate and cooperate!

Quick navigation

QR code

Contact us

Address:No. 148, yinlei Road, Laizhou City, Yantai City, Shandong

Tel:+86-0535-2213773

Fax:+86-0535-2203773

Tel:+86-13853563291

E-mail:lujun@sinterpart.com

QQ:2867251632

WeChat:鲁俊粉末冶金

Linkman: Lianlian Yu

Copyright © 2021 Laizhou Lujun Powder Metallurgy Co., Ltd. 鲁ICP备09032343号

Powered by www.300.cn This site supports IPV6 access