A kind of processing steps of Spline bushing

- Categories:Industry News

- Author:

- Origin:

- Time of issue:2021-08-17

- Views:

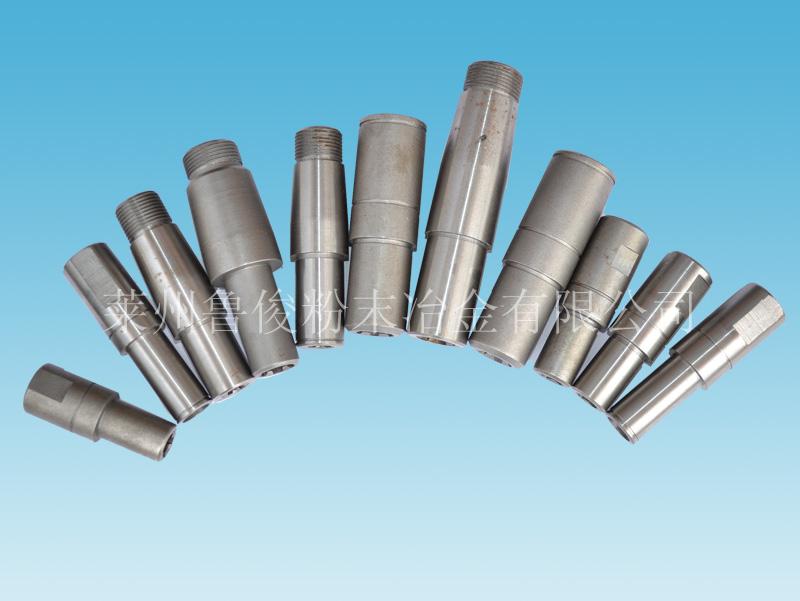

(Summary description)A Spline bushing processing technique is characterized in that: the specific steps of the Spline bushing processing technique are as follows.

A kind of processing steps of Spline bushing

(Summary description)A Spline bushing processing technique is characterized in that: the specific steps of the Spline bushing processing technique are as follows.

- Categories:Industry News

- Author:

- Origin:

- Time of issue:2021-08-17 19:05

- Views:

A Spline bushing processing technique is characterized in that: the specific steps of the Spline bushing processing technique are as follows:

1: Raw material melting: select carbon steel with a carbon content of 0.2%, heat the selected carbon steel to 1450 degrees Celsius-1500 degrees Celsius for melting treatment, and heat the molten carbon steel solution for 6-8 minutes;

2: Forming: evenly apply a release coating on the inner wall of the Spline bushing mold to be produced, pour the molten carbon steel solution in step 1 into the Spline bushing mold, and apply the carbon steel solution in the Spline bushing mold Cooling treatment, take out the molded sleeve cooled to room temperature and set aside;

3: Annealing treatment: take the casing formed in step 2 and anneal its appearance, gradually heat the formed casing to 40-50 degrees Celsius above the hypoeutectoid steel, and place the heated formed casing Slowly cool in a constant temperature chamber, and take out the formed casing after cooling to room temperature to reduce the hardness of the casing and improve its toughness;

4: Cutting teeth: Firstly, cut the undercut groove on the inner wall of the annealed casing, and set up the inner spline pattern by gradually increasing the depth. After one spline is processed, proceed to the next inner spline pattern processing step until the All the lines are cut out, and the turning tool of the machine tool exits from the undercut groove;

5: Tooth surface finishing: Obtain the semi-finished Spline bushing after tooth cutting in step 4, and use laser to detect whether the lines of the inner spline meet the usage standards. After the inspection, the areas with insufficient precision are polished to make the processed Spline bushing Suitable for normal use, ultrasonic flaw detection, check whether there are cracks, and any cracks that do not meet the standard will be scrapped;

6: Carburizing treatment: Obtain the qualified product after the finishing treatment in step 5, heat up the temperature to 900-950 degrees Celsius, and perform surface carburizing treatment on the inner and outer walls of the Spline bushing;

7: Quenching and tempering: the carburized Spline bushing is quenched, the quenching temperature is heated to 700-800 degrees Celsius, and water-cooled quenching is performed, and the quenched Spline bushing is heated to 500-520 degrees Celsius and stored at a constant temperature for 2 hours. Then place it in the air to cool slowly.

Scan the QR code to read on your phone

Interactive message

-

Tel

-

Tel

-

Back to top

Our company cooperate with hundreds of well-known enterprises such as automobile bearing, gasoline / diesel engine, textile machinery, food machinery, agricultural machinery, home appliances, motor, electric tools industry for a long time and enjoy a good reputation. Some products are exported to developed countries such as Europe and the United States. Welcome new and old customers come to negotiate and cooperate!

Quick navigation

QR code

Contact us

Address:No. 148, yinlei Road, Laizhou City, Yantai City, Shandong

Tel:+86-0535-2213773

Fax:+86-0535-2203773

Tel:+86-13853563291

E-mail:lujun@sinterpart.com

QQ:2867251632

WeChat:鲁俊粉末冶金

Linkman: Lianlian Yu

Copyright © 2021 Laizhou Lujun Powder Metallurgy Co., Ltd. 鲁ICP备09032343号

Powered by www.300.cn This site supports IPV6 access