What is the role of Spline bushing

- Categories:Industry News

- Author:

- Origin:

- Time of issue:2021-08-09

- Views:

(Summary description)Both Spline bushing and spline shafts transmit mechanical torque. The spline connection is composed of an inner spline and an outer spline.

What is the role of Spline bushing

(Summary description)Both Spline bushing and spline shafts transmit mechanical torque. The spline connection is composed of an inner spline and an outer spline.

- Categories:Industry News

- Author:

- Origin:

- Time of issue:2021-08-09 14:26

- Views:

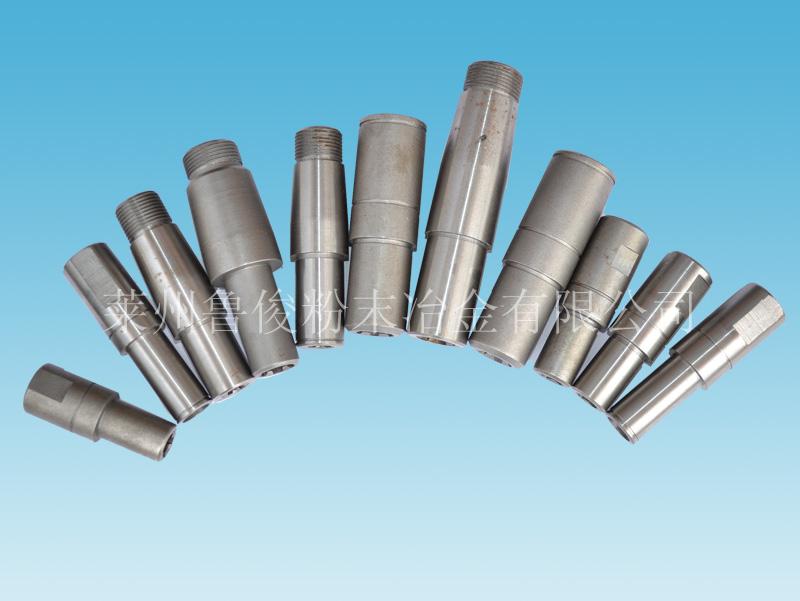

Both Spline bushing and spline shafts transmit mechanical torque. The spline connection is composed of an inner spline and an outer spline. The inner and outer splines are multi-tooth parts, the splines on the inner cylindrical surface are inner splines, and the splines on the outer cylindrical surface are outer splines. Therefore, Spline bushing is actually an internal spline, and the spline shaft is an external spline.

According to different tooth shapes, spline connections can be divided into rectangular splines and involute splines. Both types of splines have been standardized.

Spline bushing applicable occasions: connections requiring high centering accuracy, large transmission torque or frequent slippage.

Due to the difference in structure and manufacturing process of Spline bushing, compared with flat key connection, Spline bushing connection has the following characteristics in terms of strength, process and use:

1. Because more teeth and grooves are directly and evenly formed on the shaft and the hub hole, the spline joint receives more uniform force;

2. Because the groove is shallower, the stress concentration at the tooth root is less, and the strength of the shaft and hub is less weakened;

3. The number of teeth is large, and the total contact area is large, so it can bear a large load;

4. Good alignment between the parts on the shaft and the shaft, which is very important for high-speed and precision machines;

5. Good orientation, which is very important for dynamic connection;

6. Grinding method can be used to improve machining accuracy and connection quality;

7. The manufacturing process is more complicated, sometimes requires special equipment, and the cost is higher.

Scan the QR code to read on your phone

Interactive message

-

Tel

-

Tel

-

Back to top

Our company cooperate with hundreds of well-known enterprises such as automobile bearing, gasoline / diesel engine, textile machinery, food machinery, agricultural machinery, home appliances, motor, electric tools industry for a long time and enjoy a good reputation. Some products are exported to developed countries such as Europe and the United States. Welcome new and old customers come to negotiate and cooperate!

Quick navigation

QR code

Contact us

Address:No. 148, yinlei Road, Laizhou City, Yantai City, Shandong

Tel:+86-0535-2213773

Fax:+86-0535-2203773

Tel:+86-13853563291

E-mail:lujun@sinterpart.com

QQ:2867251632

WeChat:鲁俊粉末冶金

Linkman: Lianlian Yu

Copyright © 2021 Laizhou Lujun Powder Metallurgy Co., Ltd. 鲁ICP备09032343号

Powered by www.300.cn This site supports IPV6 access