The manufacturer of Metallurgy core shaft will show you how to improve the service life of the core shaft

- Categories:Industry News

- Author:

- Origin:

- Time of issue:2021-07-12

- Views:

(Summary description)The manufacturer of Metallurgy core shaft tells you that the mandrel is used as a processing and manufacturing tool in the factory. Its function is that other roller products cannot be replaced. Of course, the quality of the mandrel is also very high.

The manufacturer of Metallurgy core shaft will show you how to improve the service life of the core shaft

(Summary description)The manufacturer of Metallurgy core shaft tells you that the mandrel is used as a processing and manufacturing tool in the factory. Its function is that other roller products cannot be replaced. Of course, the quality of the mandrel is also very high.

- Categories:Industry News

- Author:

- Origin:

- Time of issue:2021-07-12 16:55

- Views:

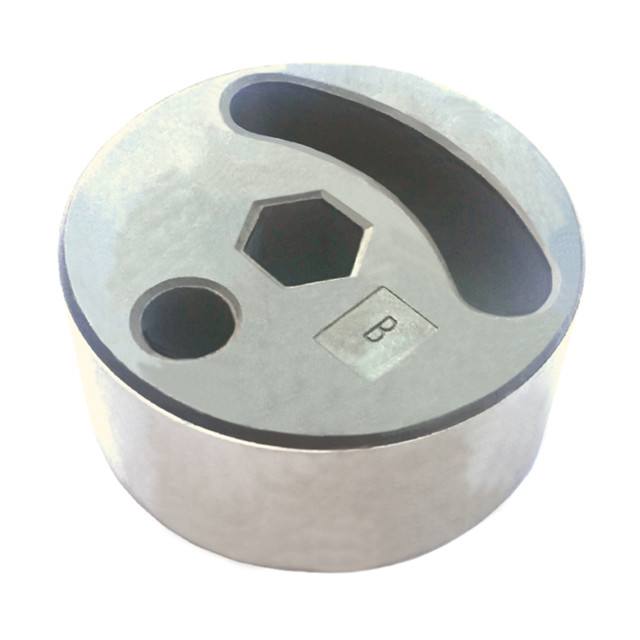

The manufacturer of Metallurgy core shaft tells you that the mandrel is used as a processing and manufacturing tool in the factory. Its function is that other roller products cannot be replaced. Of course, the quality of the mandrel is also very high. The manufacturer of Metallurgy core shaft tells you that the core shaft will have various wear problems after a period of time. If it is serious, the core shaft may not continue to work. Today, I will share with you how to improve the service life of the core shaft. Interested readers can follow the Metallurgy core shaft manufacturers to learn about it.

The manufacturer of Metallurgy core shaft tells you that the service life of the core shaft is generally 8 hours. After that, groove wear and crack fatigue will appear. If the groove caused by wear is deep, sticking and jamming will occur. Plasma aluminum guide roller has obvious resistance to abrasive wear and thermal fatigue. After repairing the mandrel, the effect is obvious. The manufacturer of Metallurgy core shaft tells you that the plasma cladding technology can be doped with high-temperature wear-resistant alloy coatings to improve the wear and crack resistance of the core shaft. The manufacturer of Metallurgy core shaft tells you that the application of plasma cladding technology on the mandrel reduces the labor intensity caused by frequent replacement and reduces the rolling work time wasted by the disassembly and transportation of the mandrel, and can increase the amount of rolled steel. It saves a lot of high-quality steel, and at the same time avoids quality problems caused by damage to the mandrel.

The above is the method to improve the service life of the mandrel, and the help to relevant people should be relatively large. The manufacturer of Metallurgy core shaft tells you that there are many types of mandrels on the market, and the difference in mandrel materials will have a great impact on the quality of the mandrel, as well as the performance of the mandrel. For professional Metallurgy core shaft manufacturers, mandrel production needs to be carried out in accordance with regular procedures. Improper operation during the production process will greatly affect the quality of the mandrel.

Scan the QR code to read on your phone

Interactive message

-

Tel

-

Tel

-

Back to top

Our company cooperate with hundreds of well-known enterprises such as automobile bearing, gasoline / diesel engine, textile machinery, food machinery, agricultural machinery, home appliances, motor, electric tools industry for a long time and enjoy a good reputation. Some products are exported to developed countries such as Europe and the United States. Welcome new and old customers come to negotiate and cooperate!

Quick navigation

QR code

Contact us

Address:No. 148, yinlei Road, Laizhou City, Yantai City, Shandong

Tel:+86-0535-2213773

Fax:+86-0535-2203773

Tel:+86-13853563291

E-mail:lujun@sinterpart.com

QQ:2867251632

WeChat:鲁俊粉末冶金

Linkman: Lianlian Yu

Copyright © 2021 Laizhou Lujun Powder Metallurgy Co., Ltd. 鲁ICP备09032343号

Powered by www.300.cn This site supports IPV6 access