Some basic conditions when using Metallurgy core shaft

- Categories:Industry News

- Author:

- Origin:

- Time of issue:2021-07-19

- Views:

(Summary description)Metallurgy core shaft is one of the roller products. It is used in many manufacturing industries, and it also plays an indispensable role in machinery and equipment. I don’t know how much you know about the Metallurgy core shaft.

Some basic conditions when using Metallurgy core shaft

(Summary description)Metallurgy core shaft is one of the roller products. It is used in many manufacturing industries, and it also plays an indispensable role in machinery and equipment. I don’t know how much you know about the Metallurgy core shaft.

- Categories:Industry News

- Author:

- Origin:

- Time of issue:2021-07-19 15:01

- Views:

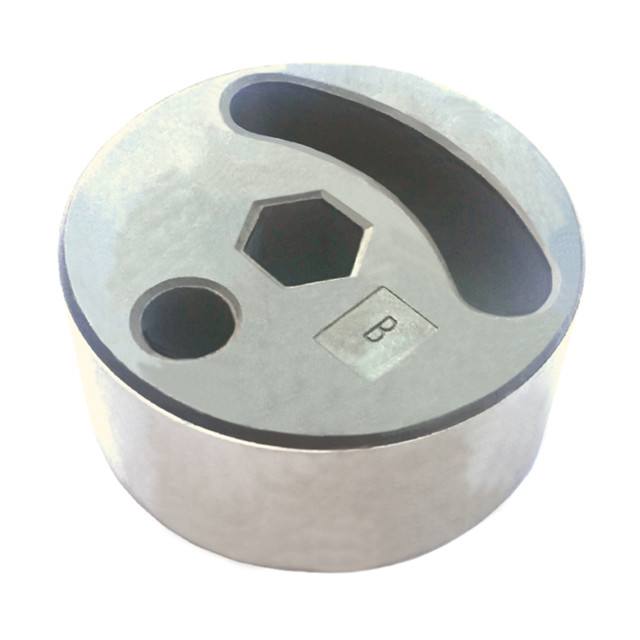

Metallurgy core shaft is one of the roller products. It is used in many manufacturing industries, and it also plays an indispensable role in machinery and equipment. I don’t know how much you know about the Metallurgy core shaft. The specifications and types of the Metallurgy core shaft vary. You need to understand your actual needs before buying. We need to understand the use of Metallurgy core shaft in order to play its role. In this article, we will introduce some basic conditions of the use of Metallurgy core shaft.

Residual stress and thermal stress will occur in the preparation process of Metallurgy core shaft before production and use. It is further subjected to the effects of various periodic stresses during use, including twists, changes, shear, contact stress, and thermal stress. The distribution of these stresses along the roll body is uneven and constantly changing. The reason is not only the planning factors, but also the continuous changes in the wear, temperature and roll shape of the Metallurgy core shaft during use. If the Metallurgy core shaft is not properly cooled after use, it will also suffer from thermal stress. Therefore, in addition to wear, the Metallurgy core shaft often exhibits various partial damages and surface damages such as cracks, fractures, peeling, and indentation. A good Metallurgy core shaft should have a better match between its strength and various other performance indicators. In this way, it is not only used for a long time under normal conditions, but also has less damage when some abnormal conditions appear. Therefore, when making the Metallurgy core shaft, the metallurgical quality of the Metallurgy core shaft must be strictly controlled or supplemented by external measures to enhance the bearing capacity.

The above is an introduction to the use of Metallurgy core shaft for everyone. After understanding this knowledge, we can use Metallurgy core shaft well and play the role of Metallurgy core shaft. When different manufacturers produce Metallurgy core shafts, the technical methods and materials used are different, so the quality of Metallurgy core shafts is very different. If we want to buy high-quality Metallurgy core shafts, we still need to be serious and reliable. Shaft manufacturers, you can shop around or listen to friends to learn more.

Scan the QR code to read on your phone

Interactive message

-

Tel

-

Tel

-

Back to top

Our company cooperate with hundreds of well-known enterprises such as automobile bearing, gasoline / diesel engine, textile machinery, food machinery, agricultural machinery, home appliances, motor, electric tools industry for a long time and enjoy a good reputation. Some products are exported to developed countries such as Europe and the United States. Welcome new and old customers come to negotiate and cooperate!

Quick navigation

QR code

Contact us

Address:No. 148, yinlei Road, Laizhou City, Yantai City, Shandong

Tel:+86-0535-2213773

Fax:+86-0535-2203773

Tel:+86-13853563291

E-mail:lujun@sinterpart.com

QQ:2867251632

WeChat:鲁俊粉末冶金

Linkman: Lianlian Yu

Copyright © 2021 Laizhou Lujun Powder Metallurgy Co., Ltd. 鲁ICP备09032343号

Powered by www.300.cn This site supports IPV6 access