What are the advantages of powder metallurgy auto parts

- Categories:Industry News

- Author:

- Origin:

- Time of issue:2023-02-09

- Views:

(Summary description)The manufacturer of powder metallurgy auto parts tells you that we can choose powder metallurgy bearings from powder metallurgy gear manufacturers with different oil content according to different working conditions. When the oil content is large, it can be applied without supplementary lubricating oil and under low load.

What are the advantages of powder metallurgy auto parts

(Summary description)The manufacturer of powder metallurgy auto parts tells you that we can choose powder metallurgy bearings from powder metallurgy gear manufacturers with different oil content according to different working conditions. When the oil content is large, it can be applied without supplementary lubricating oil and under low load.

- Categories:Industry News

- Author:

- Origin:

- Time of issue:2023-02-09 15:57

- Views:

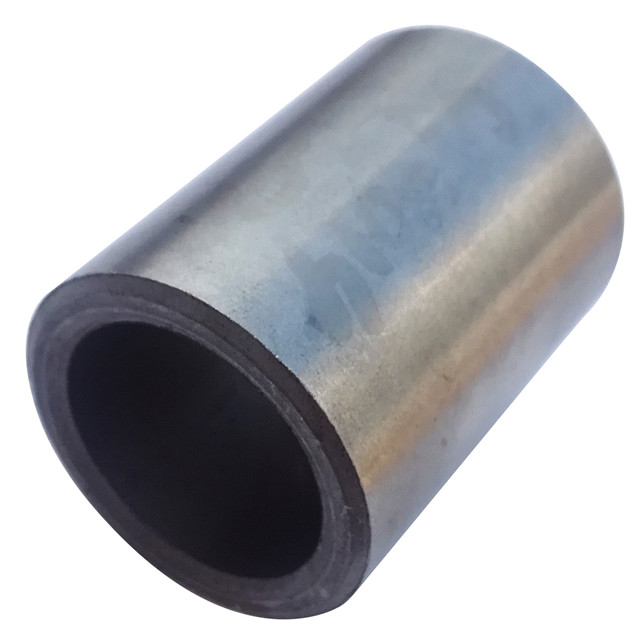

The manufacturer of powder metallurgy auto parts tells you that we can choose powder metallurgy bearings from powder metallurgy gear manufacturers with different oil content according to different working conditions. When the oil content is large, it can be applied without supplementary lubricating oil and under low load; when the oil content is small, it can be applied under heavy load and high speed; powder metallurgy bearings containing graphite, because graphite itself has lubricity, its disadvantage is that its strength is relatively low Low; In the case of no corrosion, it can be considered to choose cheap and high-strength iron-based powder metallurgy bearings, but the hardness of the matching journal should be appropriately increased.

Advantages of powder metallurgy bearings: The powder metallurgy auto parts manufacturer tells you that powder metallurgy bearings are also called oil-impregnated bearings. The oil-impregnated bearings are in the non-operating state, and the lubricating oil fills their pores. Small, then, the lubricating oil overflows and enters the bearing clearance. When the shaft stops rotating, the bearing pad cools down, the porosity recovers, and the lubricating oil is sucked back into the porosity. Although it is possible to form a complete oil film in an oil-impregnated bearing, in most cases, this kind of bearing is in a mixed friction state with an incomplete oil film.

Powder metallurgy bearings are widely used in: electric tools, motor industry, automobile and motorcycle industry, office equipment, home appliance industry, digital products, textile machinery, packaging machinery and other mechanical equipment.

Generally speaking, powder metallurgy bearings are mainly made of raw material powder through pressing, sintering, shaping, oil immersion and other processes. The manufacturer of powder metallurgy auto parts tells you that most of the machines now have a relatively high degree of automation. The daily output is relatively large, and most products can be formed at one time, so the larger the batch, the better the production. Moreover, if the number of molds used is less, hundreds of thousands may be made, and if more molds are used, more than one million may be made. But the cost of the mold is relatively high, so it is not easy to do it if the batch is small, and it takes a long time to change the mold.

Scan the QR code to read on your phone

Interactive message

-

Tel

-

Tel

-

Back to top

Our company cooperate with hundreds of well-known enterprises such as automobile bearing, gasoline / diesel engine, textile machinery, food machinery, agricultural machinery, home appliances, motor, electric tools industry for a long time and enjoy a good reputation. Some products are exported to developed countries such as Europe and the United States. Welcome new and old customers come to negotiate and cooperate!

Quick navigation

QR code

Contact us

Address:No. 148, yinlei Road, Laizhou City, Yantai City, Shandong

Tel:+86-0535-2213773

Fax:+86-0535-2203773

Tel:+86-13853563291

E-mail:lujun@sinterpart.com

QQ:2867251632

WeChat:鲁俊粉末冶金

Linkman: Lianlian Yu

Copyright © 2021 Laizhou Lujun Powder Metallurgy Co., Ltd. 鲁ICP备09032343号

Powered by www.300.cn This site supports IPV6 access