Metallurgy core shaft structure and function introduction

- Categories:Industry News

- Author:

- Origin:

- Time of issue:2021-07-26

- Views:

(Summary description)Metallurgy core shaft is a mechanical part that connects rotating parts. The main function is to realize the connection between the parts, so that the equipment can work normally. Therefore, the Metallurgy core shaft is very important and plays an indispensable role in the operation of the equipment.

Metallurgy core shaft structure and function introduction

(Summary description)Metallurgy core shaft is a mechanical part that connects rotating parts. The main function is to realize the connection between the parts, so that the equipment can work normally. Therefore, the Metallurgy core shaft is very important and plays an indispensable role in the operation of the equipment.

- Categories:Industry News

- Author:

- Origin:

- Time of issue:2021-07-26 15:06

- Views:

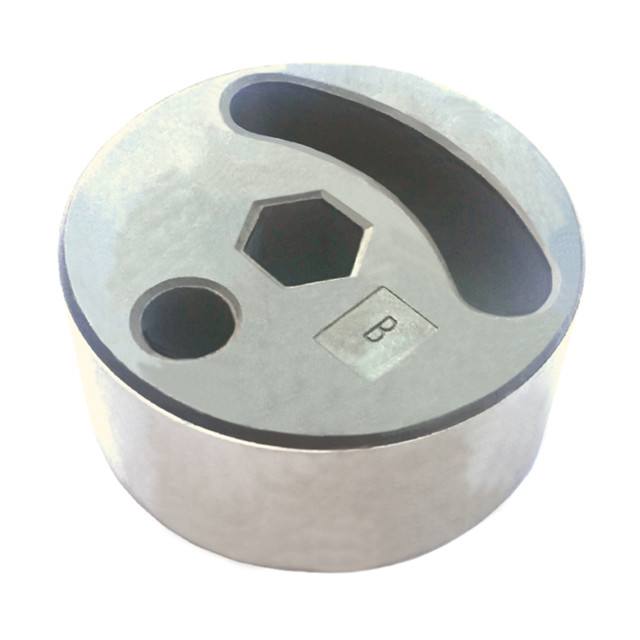

Metallurgy core shaft is a mechanical part that connects rotating parts. The main function is to realize the connection between the parts, so that the equipment can work normally. Therefore, the Metallurgy core shaft is very important and plays an indispensable role in the operation of the equipment. Understanding the knowledge of the Metallurgy core shaft can help us better use the Metallurgy core shaft and reflect the value of the Metallurgy core shaft. So first of all, we need to know the structure of the Metallurgy core shaft to understand how the Metallurgy core shaft performs its functions.

The Metallurgy core shaft includes a connecting section, a rotating section and a fixed section. One end of the rotating section is connected to the connecting section, and the other end of the rotating section is connected to the fixed section. The end of the fixed section is provided with a through hole. A baffle is provided in the cavity, one end of the rotating shaft is fixedly connected to the middle side wall of the connecting rod, a spring is provided on the side of the baffle close to the rotating shaft, and the spring penetrates through the through hole to connect to the clamping block. There is a groove on one side of the block. This standard Metallurgy core shaft has a simple structure. By adding connecting rods and clamping blocks, it is convenient for other parts to be clamped and stabilized, preventing the parts from falling off when the Metallurgy core shaft is rotating and passing The spring facilitates the movement of the clamping block, and the fixed section can be easily inserted through the through hole of the part, which improves the installation efficiency and maintenance efficiency of the part. This structure is convenient for clamping, convenient for fixing the connector, and convenient for installation, use and replacement of the Metallurgy core shaft.

The knowledge of the structure and function of the Metallurgy core shaft has been introduced here. I believe that all readers must understand it very clearly. The types of Metallurgy core shafts are quite diverse. According to different usage requirements, our standards for purchasing Metallurgy core shafts are also different. When purchasing, we need to consider multiple aspects. Choosing the right precision Metallurgy core shaft is definitely beneficial to the use of our equipment and production assistance. You can choose carefully.

Scan the QR code to read on your phone

Interactive message

-

Tel

-

Tel

-

Back to top

Our company cooperate with hundreds of well-known enterprises such as automobile bearing, gasoline / diesel engine, textile machinery, food machinery, agricultural machinery, home appliances, motor, electric tools industry for a long time and enjoy a good reputation. Some products are exported to developed countries such as Europe and the United States. Welcome new and old customers come to negotiate and cooperate!

Quick navigation

QR code

Contact us

Address:No. 148, yinlei Road, Laizhou City, Yantai City, Shandong

Tel:+86-0535-2213773

Fax:+86-0535-2203773

Tel:+86-13853563291

E-mail:lujun@sinterpart.com

QQ:2867251632

WeChat:鲁俊粉末冶金

Linkman: Lianlian Yu

Copyright © 2021 Laizhou Lujun Powder Metallurgy Co., Ltd. 鲁ICP备09032343号

Powered by www.300.cn This site supports IPV6 access