Processing technology of Metallurgy core shaft

- Categories:Industry News

- Author:

- Origin:

- Time of issue:2021-08-02

- Views:

(Summary description)my country's manufacturing technology has made great progress. We have also moved from introducing foreign processing and manufacturing equipment to now using Chinese-made equipment. It can be seen that my country's manufacturing and manufacturing progress is still very large.

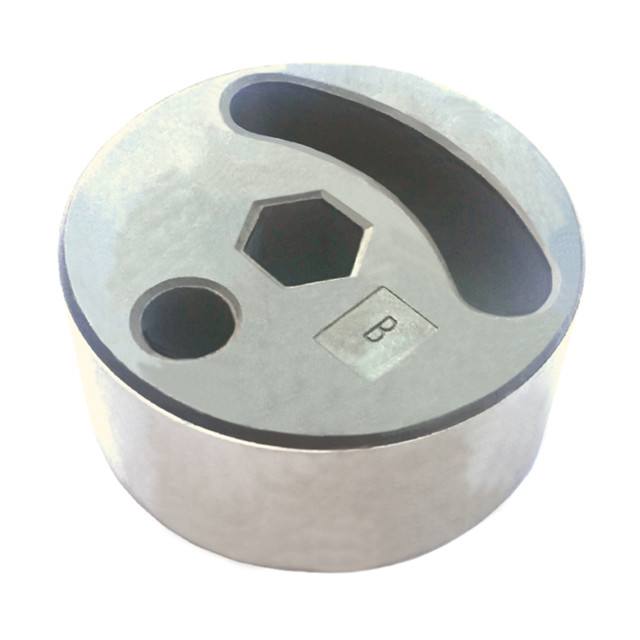

Processing technology of Metallurgy core shaft

(Summary description)my country's manufacturing technology has made great progress. We have also moved from introducing foreign processing and manufacturing equipment to now using Chinese-made equipment. It can be seen that my country's manufacturing and manufacturing progress is still very large.

- Categories:Industry News

- Author:

- Origin:

- Time of issue:2021-08-02 16:16

- Views:

my country's manufacturing technology has made great progress. We have also moved from introducing foreign processing and manufacturing equipment to now using Chinese-made equipment. It can be seen that my country's manufacturing and manufacturing progress is still very large. When a device is manufactured, there are many accessories that need to be used, which is why it is difficult to manufacture the device. Nowadays, many equipments may need to use Metallurgy core shaft when manufacturing. The production of a separate Metallurgy core shaft also takes a lot of time. Interested readers can learn about the processing technology of the Metallurgy core shaft. The following is a brief introduction to the knowledge of the Metallurgy core shaft.

1. Component welding: group welding of inner plate, shaft head, bushing, blocking plate, inner tube, etc.

2. Fitting, assembly and welding: match the inner tube, size and outer tube of the car with 0.4mm interference, the two-plate back welding angle is 15X30 degrees, polish the inner tube, clean the slag, and check whether the inner tube size and the inner diameter of the outer tube are dimensioned Adaptable, the heating sleeve is in place, after cooling and shrinking, the whole assembly welding

3. Annealing, rough turning, quenching: annealing heat treatment, process quenching and tempering, multiple stress relief, rough turning left margin, static balance, more than 50g, need to calculate the amount of bias, on the lathe to borrow the car.

Fourth, fine turning, rough grinding: two-axis head repairs the pin hole, the two-axis head jumps to the roller surface, the grinding support circle is used as the bracket position, and the grinding roller surface size is required according to the drawing.

5. Dynamic balance, electroplating, fine grinding: sealing the vent hole, do pressure test without leakage, do water pressure unblocking test. Hard chromium electroplating, 0.15 chromium layer on one side is uniform without pinholes, shedding and other defects.

6. Matte and fine grinding surface: Use a disc grinder to grind the Metallurgy core shaft to inspect the surface without water ripples, spiral patterns, pinholes, flies and other defects.

These are some of the processing techniques that Metallurgy core shaft needs to involve. The existence of each processing technique is to improve the experience that Metallurgy core shaft can bring, and it is necessary for Metallurgy core shaft manufacturers to study these processing techniques in detail. In fact, Metallurgy core shaft is rarely used in life. Its value is mainly in industrial production. Readers should have a more in-depth understanding of Metallurgy core shaft through the introduction of this article. If you want to know more about Metallurgy core shaft, or if you want to buy Metallurgy core shaft products on our official website, you can directly call the hotline to contact customer service, and they will provide you with more professional help.

Scan the QR code to read on your phone

Interactive message

-

Tel

-

Tel

-

Back to top

Our company cooperate with hundreds of well-known enterprises such as automobile bearing, gasoline / diesel engine, textile machinery, food machinery, agricultural machinery, home appliances, motor, electric tools industry for a long time and enjoy a good reputation. Some products are exported to developed countries such as Europe and the United States. Welcome new and old customers come to negotiate and cooperate!

Quick navigation

QR code

Contact us

Address:No. 148, yinlei Road, Laizhou City, Yantai City, Shandong

Tel:+86-0535-2213773

Fax:+86-0535-2203773

Tel:+86-13853563291

E-mail:lujun@sinterpart.com

QQ:2867251632

WeChat:鲁俊粉末冶金

Linkman: Lianlian Yu

Copyright © 2021 Laizhou Lujun Powder Metallurgy Co., Ltd. 鲁ICP备09032343号

Powered by www.300.cn This site supports IPV6 access